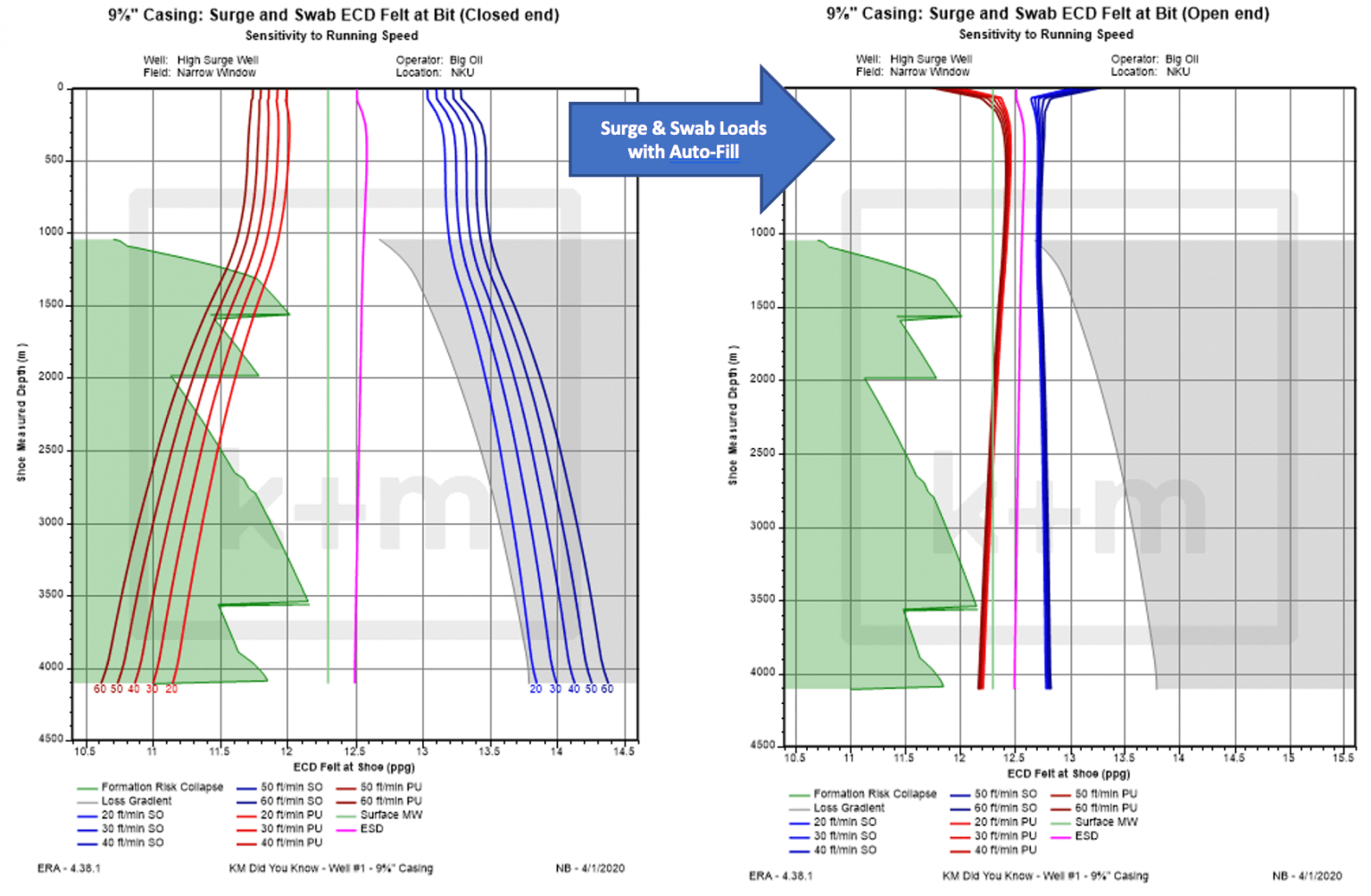

Using Auto-fill equipment reduces surge pressures and mitigate risk of mud losses during tight clearance casing deployment? High surge pressure can result in mud losses and formation damage, which can jeopardize successful cement placement and zonal isolation. Accurate modeling of surge pressures with open and closed string set up during planning stage will help you evaluate if the use of auto-fill equipment can be beneficial to your operations, without the need for costly design changes to your well! What is happening: Due to low annular clearance, surge loads can exceed the formation loss gradient even at low running speed. This is particularly apparent in challenging wells with narrow mud window, such as Extended Reach or deep-water projects. If running the casing conventionally as closed ended, the fluid in the annulus is pushed up-ward generating high surge pressure; however, with the installation of auto-fill, the drilling fluid will flow freely into and up the casing, reducing both the surge and swab pressure loads felt by the formation. Reducing surge pressure will mitigate risk of mud losses and also can allow increased running speed. To ensure useful application of auto-fill equipment, optimum hole cleaning and following equipment operating procedures will you help mitigate risk of tool plugging or auto-conversion during the run.