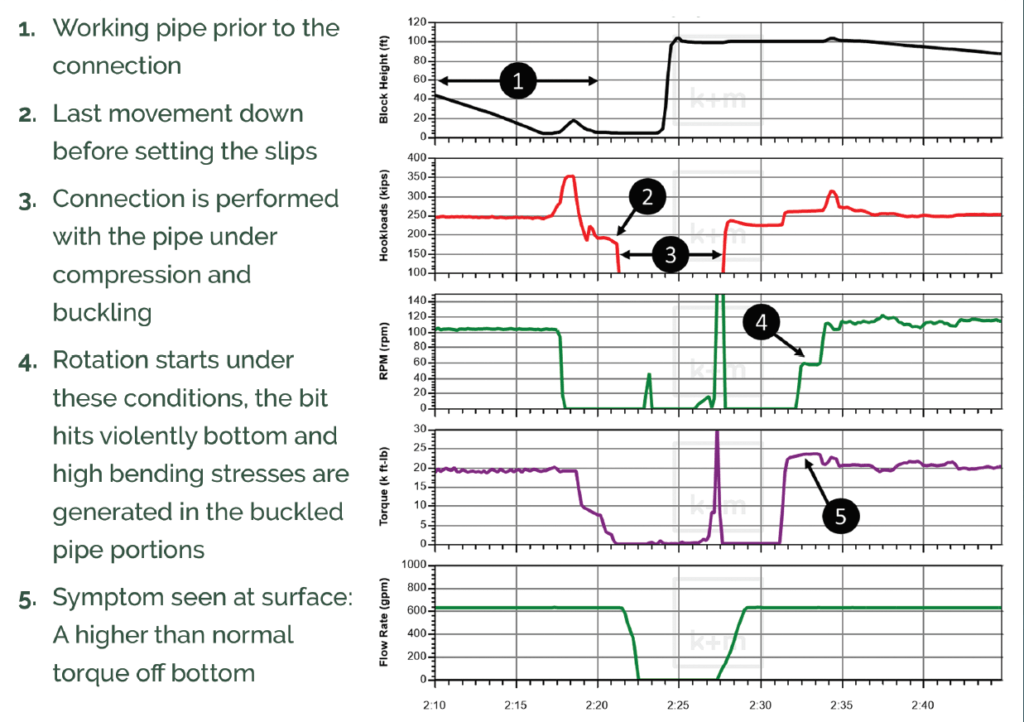

The Time Plot Below, Shows The Sequence Of The Connection At This Depth:

During connections, setting the slips under compression in high angle wells can lead to a bit / BHA components damage or drill pipe failure. The drill pipe must be set in slips with a tension very close to the Rotating Off Bottom Weight.

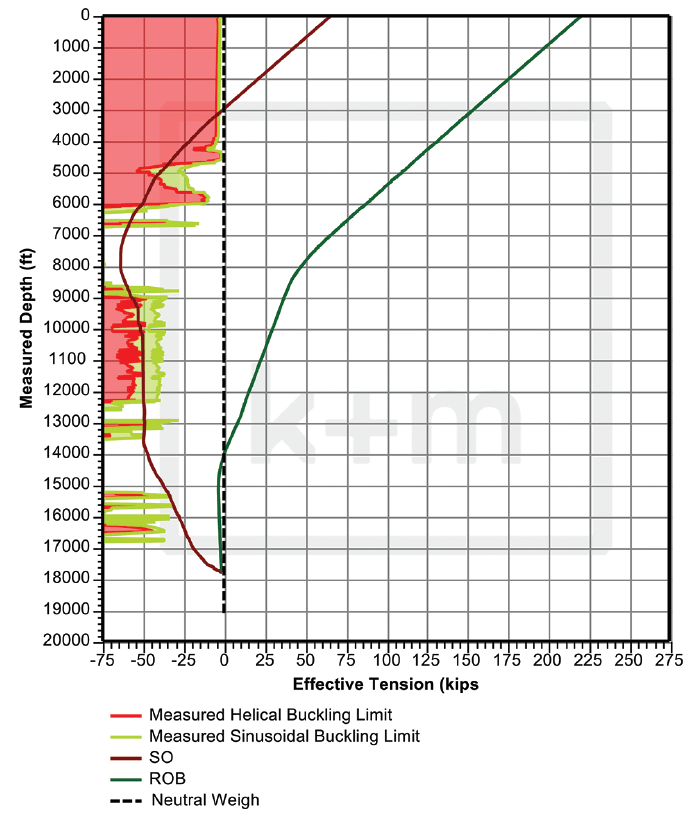

What is happening? In high angle and horizontal wells, a large portion of the drill pipe must be compressed to push the bit when tripping-in or moving down the pipe during a connection. The total drill string length under this condition is less than rotation off bottom. If the relative stretch between Rotation Off Bottom (ROB) and Slacking Off (SO) is larger than the distance to bottom and the pipe was set in slips under compression, when rotation starts after the connection, the pipe will quickly stretch to the ROB length and can hit violently bottom, potentially damaging the bit or any of the BHA components. Also, rotating a buckled drill pipe generates high bending stresses, which may cause failure by fatigue.

The example below shows how a connection at ~17,800′ in a horizontal well. Tripping in or sliding the string puts the drill pipe in portions of the mid-inclination tangent and in the vertical under buckling as can be seen in the snapshot plot below these lines. In this scenario, the relative stretch ROB – SO is ~6ft.