There seems to be a belief that doglegs are “smoothed out” while drilling and especially after casing runs.

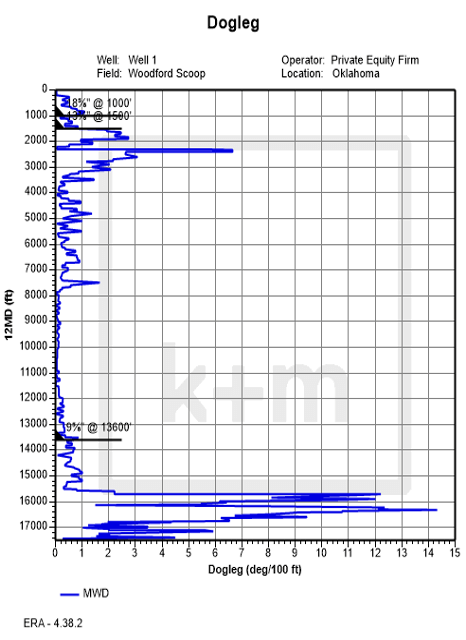

- In the example below, a well was sidetracked due to a shallow fish that was left in hole.

- The well was a deep TVD well with high tension loads across the shallow doglegs at the sidetrack point. This resulted in high normal forces and risks causing a casing wear problem.

- Given a fixed tension load, the normal forces are directly proportional to the size of the dogleg.

- A gyro was run to determine how much lower the doglegs were after running the intermediate casing across the sidetrack point.

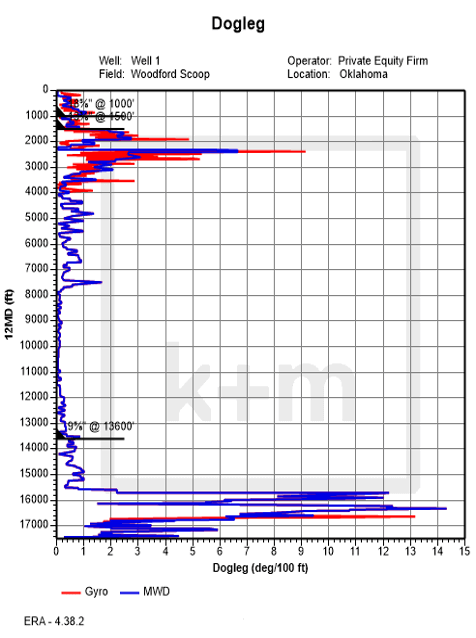

- The result of the gyro confirmed that the doglegs had not been reduced and in fact were higher than measured with the MWD. The first graph below shows the MWD survey. The second graph shows the Gyro survey compared to the MWD.

- Confirming that the doglegs still posed a significant risk of wear to the casing resulted in the operator utilizing non-rotating drill pipe protectors (NRDPPs) to drill the 8½” section to protect the 9⅝” casing.