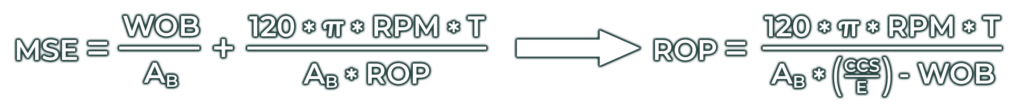

ERA Software has a Predictive ROP Algorithm – it’s fast and easy to use and one more tool in the box for improving ROP and overall performance improvement. The concept is a simple one, we basically take the MSE Equation and re-arrange it to solve for ROP:

Note that there’s a couple of new parameters needed: CCS (Confined Compressive Strength) – Project Geologists should be able to provide this, calculated from log data, or help you come up with an intelligent way to estimate it, and E (efficiency ratio) – this is part of standard MSE work and we typically assume it to be 0.35 for most typical drilling operations – but Predictive ROP we are able to dial it in and really calibrate our model!

You will find the option for Predictive ROP in your Drilling Subops, look on the bottom right and click the check box.

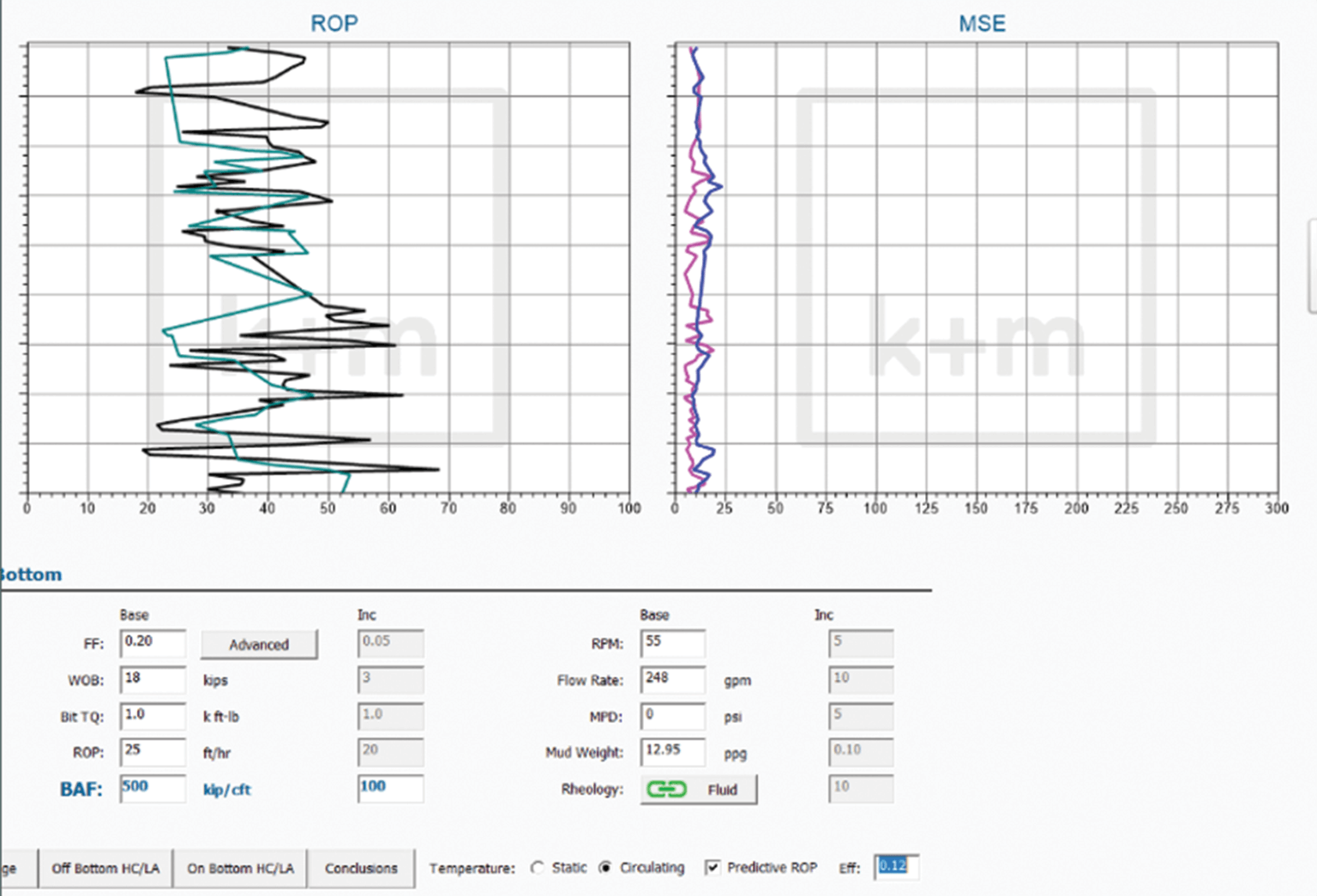

Setting the model up takes just 2 easy steps: 1- adjust your Mechanical Efficiency (Eff) so that the MSE curves lines up with the CCS curve (we’ve now calibrated the model for efficiency of the drilling system), 2- Adjusted the BAF (Bit Aggressivity Factor), this parameters accounts for different cuttings structures with each particular bit, adjust the number up and down until the predicted ROP lines up with actual ROP.

And now you have a calibrated ROP Model! For this Bit & BHA combination, you can use your calibrated BAF and Eff on the remainder of the current well and on future wells – play around with parameters, change mud weights, change drill pipe, add HWDP… Do your homework and drill faster!

You will find the option for Predictive ROP in your Drilling Subops, look on the bottom right and click the check box.