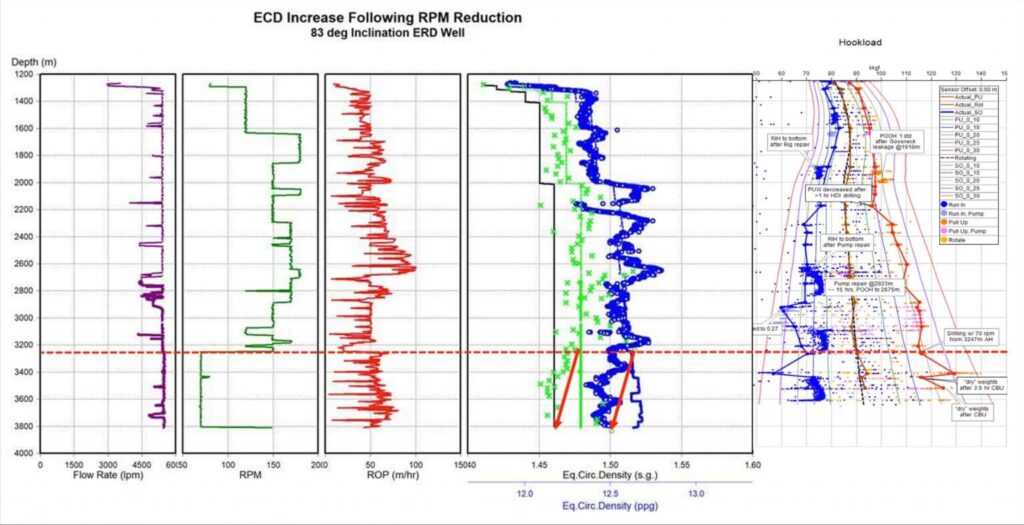

Did you know that in a high angle well, poor hole cleaning results in lower ECD? This is contrary to the popular belief that ECD increases when hole cleaning is poor. The reason that ECD decreases with poor hole cleaning is that only cuttings suspended in the mud contributes to ECD while cuttings laying on the low side of the hole does not. When hole cleaning is poor, there will be less cuttings suspended in the mud in the near-vertical section of the well, as such, lower ECD.

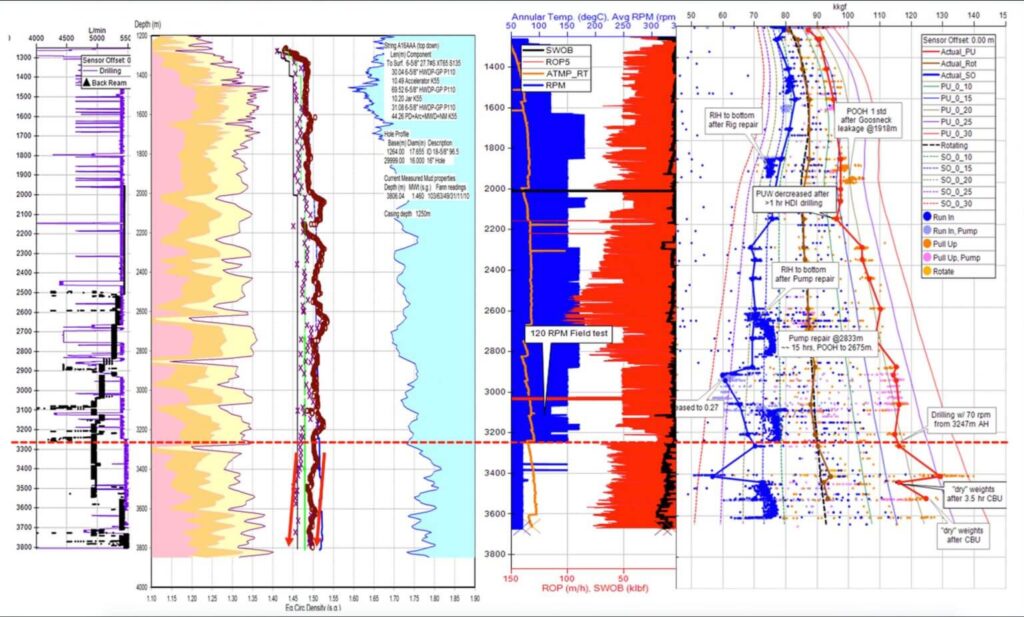

In the example below, a high angle tangent 16″ section was drilled. The rotary speed was reduced from 150 rpm to 70 rpm for directional control reasons from 3,250m (10,660′) onwards to section TD at 3,800m (12,465′). ROP remained at 50-60 m/hr (160-200 ft/ hr) while flow rate was constant at 5,500 lpm (1,450 gpm). Both pick up and slack off drag trend increased indicating insufficient hole cleaning due to the reduction in rotary speed. However, both the ESD and ECD were showing a decreasing trend from 3,250m (10,660′) onwards to section TD at 3,800m (12,465′). The measured ESD and ECD were lower than the hydraulics model prediction. This example clearly shows that ECD decreases with poor hole cleaning and lower than expected ECD relatively to the model should not be taken as everything was going well.