Rotation is a legitimate way to overcome drag.

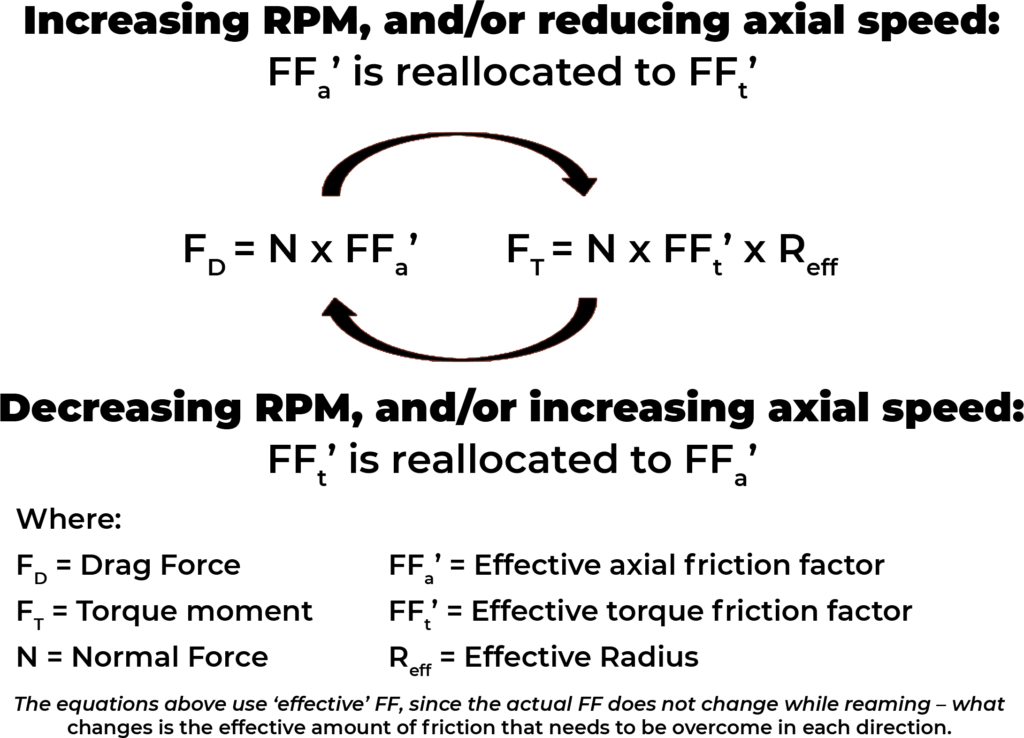

There is a fixed amount of friction that needs to be overcome to move the string, in any direction. When tripping in, all friction acts in the axial direction, and generates drag. When rotating at a fixed depth, all friction acts in the radial direction, and generates torque.

But, if the string is reamed-in, that fixed amount of friction that needs to be overcome to move the string is now shared between the axial and radial directions. The allocation of the friction into the axial and radial directions is based on velocity, i.e. RPM & pipe diameter, vs axial speed.