CHALLENGE

In high angle wells, the hole cleaning mechanisms, the application of the proper drilling and tripping practices, and the overall wellbore monitoring process is different than those used in vertical wells. Even the most experienced crews can have a “vertical hole” mentality with many misconceptions that create self-inflicted catastrophic events.

SOLUTION

Performing an Offset Well Review, most importantly, doing a comprehensive analysis of the time-based data. It is possible to identify gaps in the application of the proper drilling and tripping practices and make recommendations to reduce the impact of existing risks observed in previous wells.

RESULTS

Offset Well Reviews performed for two different operations in different environments allowed K&M to identify the poor practices, both during the design and during execution of past wells. A K&M specialist could then recommend which changes were needed in the practices. A customized operational training provided the opportunity to share the findings with the office and rig teams to implement the appropriate well monitoring and best practices.

Train-Wrecks In High Angle Wells

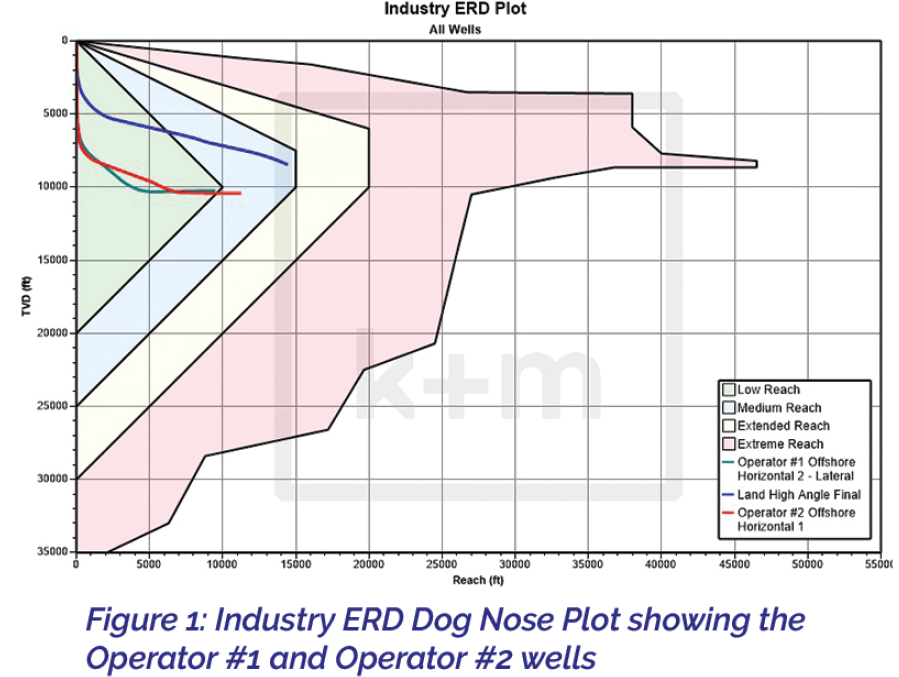

Operator #1 has been drilling medium-reach wells on land for several years. All of the wells had reached total depth, despite countless trouble during trips and casing runs. Some of the wells required to be sidetracked after packing off while tripping. Operator #2 drills offshore horizontal wells but have had problems while tripping and cementing the intermediate sections resulting in high Non Productive Time (NPT).

Both operators initially assumed the problems were more related to wellbore instability and/or tortuosity. Since they were planning to drill longer wells, both requested assistance from K&M to determine the cause of the difficulties and apply the learning to optimize the well design by mitigating any identified risks.

Identifying Gaps In Drilling Practices Application

K&M performed an Offset Well Review in both cases. The goal of this service is to gain an understating of the area drilling conditions and to identify any local hazard condition and to identify any local hazard and trends. By analyzing the different operator and service company reports and the time-based data, it’s possible to calibrate the mechanical and hydraulic models and evaluate the drilling practices utilized.

At medium and high inclinations, the cuttings behavior is different than vertical and low inclination wells. This will have a big impact on the hole cleaning mechanism, the application of the proper drilling and tripping practices, parameters, and the overall wellbore monitoring process. Typically, as a result of “vertical hole” mentality, even the most experienced crews have many misconceptions, misdiagnose warning signs, and create self-inflicted catastrophic events.

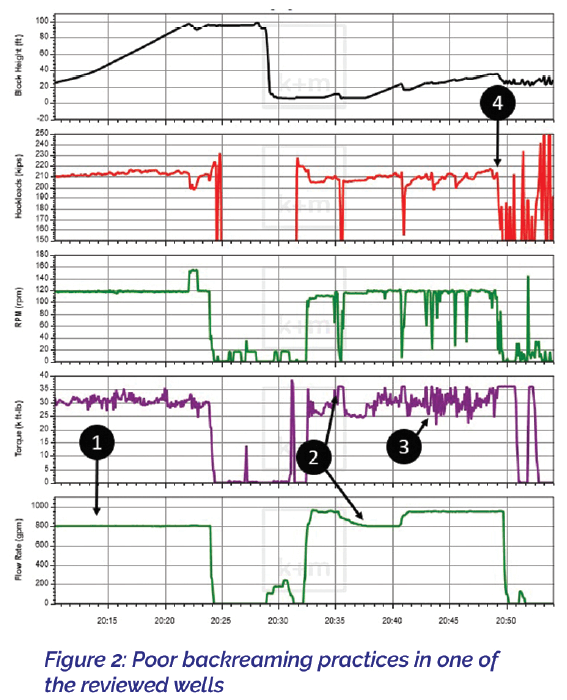

Analyzing time-based data in one of the wells, several gaps were identified in the application of the proper cleaning, tripping and backreaming practices. Figure #2 shows how backreaming was being performed with an unacceptable flow rate (1). When the torque increases (2) and (3), the flow rate decreased and the backreaming speed increased, creating the conditions to quickly pack off (4).

Improper circulation times and parameters affect not only hole cleaning but also the wellbore integrity. Poor flow rates in another well were key contributors for dynamic barite sag, which exacerbated the hole cleaning problems and led to a poor cementing operation.

Improving Practices, Sharing Knowledge

After finishing the study, the K&M specialist recommended changes in the drilling, tripping and backreaming practices to reduce the identified risks impacting the operations. These recommendations were discussed with both the operator’s drilling and completions team in a dedicated session. A 2-day operations training was performed with the office and rig teams to discuss the key operational risks and explain the best practices to be utilized for a successful operation. Specific examples from the offset wells were used to illustrate both the existing proper and poor practices. The goal of this training session was to ensure the entire drilling team was aligned in the best high angle practice to reduce self-inflicted events and to monitor the operations effectively.

In both operations, the Offset Well Review also allowed to identify the events (and lack of events) which could not be explained by the existing Geomechanics models, Calibration of the mechanical Earth Model (MEM) was deemed to be a critical step to drill the longer wells.