K&M Remote Operations Services (ROPS) identified the onset of wellbore instability by comparing streaming real-time data to Torque & Drag models tailored for the extended reach drilling environment. Client was alerted to geohazards and able to implement K&M’s recommendations for avoiding a stuck pipe event.

Challenge

- Target formation contained laterally variable fluvial deposits consisting of competent sands (pay zone) with unpredictable occurrences of unstable, fissile shales.

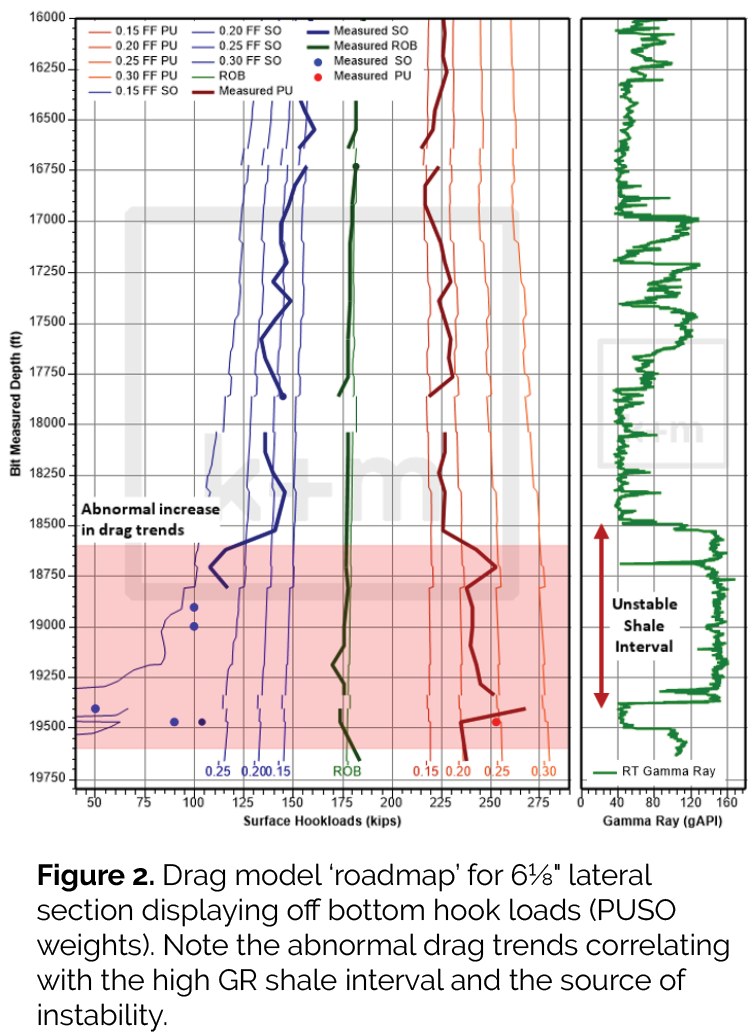

- Production lateral section drilled at 89-92° inclination and sub-parallel to bedding dip, increasing the risk of formation breakout, bedding plane instability and stuck pipe events (Figure 1). Typically, to maintain a stable wellbore, higher mud weights must be used and swabbing loads must be minimized, however geomechanical constraints in the area were limiting.

- No onsite personnel trained in identifying and reporting cavings relating to wellbore instability.

- Existing operational practices prioritized fast connections and tripping speeds, as a result previous wells experienced stuck BHAs and unsuccessful casing runs due to instability and poor management practices.

Solution

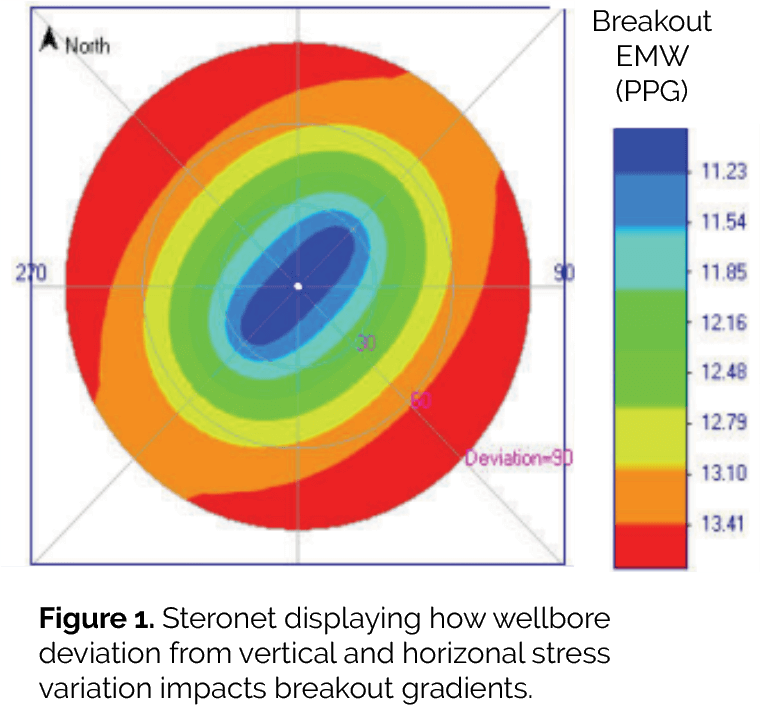

- K&M proprietary software (ERA) was used to generate torque and drag models (Figure 2) for the lateral section in order to evaluate measured pick-up (PU), slack-off (SO) hookloads and off-bottom torque data.

- K&M Remote Operations Support ensured accurate and consistent practices were conducted to obtain T&D data, i.e., how PU / SO hookloads were taken prior to connection (hook speeds, length of string movement, rotation, flowrates, etc.)

- Torque & Drag data was used to evaluate the condition of the wellbore, as it was being drilled, and identify unstable zones which would typically create issues for subsequent operations. When instability is identified, it requires an appropriate response to ensure the wellbore is clean enough for the casing run and that the BHA can be tripped safely out the hole.

Results

- Clear, abnormal drag trends were observed immediately after intersecting an unstable shale interval (Fig. 2).

- Wellsite personnel were alerted to the potential geohazard and K&M recommendations concerning mud weights, connection procedures, clean up cycles, backreaming parameters and tripping practices were implemented.

- Stuck pipe risks were reduced, the BHA was tripped out of hole successfully and casing was run to a depth isolating the unstable shale interval.

- A post job review was delivered, which provided future prevention and operational solutions to managing wellbore instability risks. These included recommendations at both the design and execution stages

- Client commissioned K&M Engineering & Geomechanical team to further investigate the optimization of their lateral design.